Rosemount 5300 Series - Superior Performance Guided Wave Radar

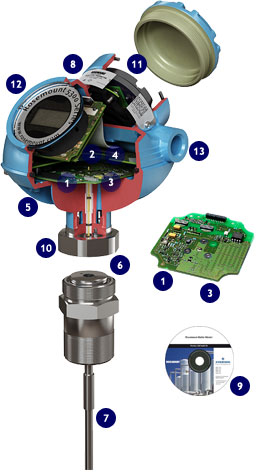

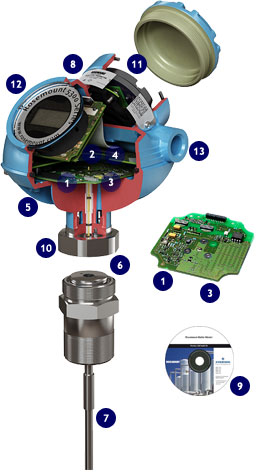

The Rosemount 5300 Series is our superior 2-wire Guided Wave Radar (GWR) for challenging level and interface measurements on liquids, slurries and solids. It leverages our 30 years of proven radar expertise and is designed to focus on your plant’s profitability. The 5300 delivers everything you would expect from a best-in-class process radar – superior reliability, state-of-the-art safety features, effortless handling, and unlimited connectivity.

Features and Benifits

Guided Wave Radar is a continuous level measurement technique that offers several advantages. It is virtually unaffected by temperature, pressure and vapor gas mixtures. It has no moving parts and therefore requires little or no maintenance. It measures the level directly and is therefore unaffected by most fluid property changes, including but not limited to density and viscosity changes. Additionally, the Rosemount 5300 Series offers the following benefits:

Higher measurement reliability and capability resulting in improved process uptime through

|

Direct Switch Technology Direct Switch Technology

Probe End Projection Probe End Projection

Smart Galvanic Interface Smart Galvanic Interface

Advanced EchoLogics and Diagnostics Robust design resulting in reduced operating costs and safety Advanced EchoLogics and Diagnostics Robust design resulting in reduced operating costs and safety

Dual Compartment aluminum or stainless steel housing with integrated Cooling Fins Dual Compartment aluminum or stainless steel housing with integrated Cooling Fins

Interchangeable transmitter head without opening the tank and no matching between head and probes Interchangeable transmitter head without opening the tank and no matching between head and probes

No mechanical moving parts and no need for re-calibration No mechanical moving parts and no need for re-calibration

Easy commissioning resulting in reduced startup costs through

Multivariable, Level and Interface from the same transmitter Multivariable, Level and Interface from the same transmitter

User-friendly configuration tool Rosemount Radar Master with Measure-and-Learn User-friendly configuration tool Rosemount Radar Master with Measure-and-Learn

Rotate housing in any direction Rotate housing in any direction

Easy to access terminals and loop-powered Easy to access terminals and loop-powered

Single assembly for quick installation Single assembly for quick installation

Existing tank openings and cabling may be used In addition, the 5300 has high application flexibility. Existing tank openings and cabling may be used In addition, the 5300 has high application flexibility.

|

|

Specifications :

|

Product

|

Model 5301 for level of liquids or submerged interfaces.

Model 5302 for level and interface in liquids.

Model 5303 for level of solids.

|

|

Measurement Principle

|

Time Domain Reflectometry (TDR)

|

|

Measuring Range

|

Up to 164 ft. (50 m)

|

|

Dielectric Constant

|

Minimum 1.2 for coaxial probe or single probe installed in bypass, other probes from 1.4. See Product Data Sheet for complete data.

|

|

Probe Materials

|

SST, Alloy 400, Alloy C276 (UNS N10276), or PTFE-covered SST

|

|

Reference Accuracy

|

± 0.1 in. (± 3 mm) or ± 0.03% of measured distance, whichever is greatest

|

|

Repeatability

|

±0.04 in. (±1 mm)

|

|

Output

|

4-20mA with superimposed digital HART® communication FOUNDATION® Fieldbus

|

|

Process Temperature

|

Up to 752 ºF (400 ºC). See Product Data Sheet for complete data

|

|

Lowest Temperature

|

From -320 ºF (-196 ºC)

|

|

Process Pressure

|

4-20mA with superimposed digital HART® communication, and FOUNDATION® Fieldbus

|

|

Ex-Approvals

|

Intrinsic Safety (IS) or Explosion-proof/Flameproof (ATEX, CSA, IECEx, FM, ...)

|

|

Display

|

5-digit integral display (Optional)

|

|

Output Variables

|

Level, Interface Level, Distance, Interface Distance, Upper Product Thickness, Volume, Level Rate, Signal Strength, Housing Internal Temperature, Aout current and % of Range

|

|

Enclosure

|

Polyurethane-covered die-cast Aluminum or stainless steel housing with dual compartments.

|

|

Ingress Protection

|

Type 4X, IP66, IP67

|

|

Fieldbus Functionality

|

Link-master device (backup LAS), PlantWeb Alerts, Methods

|

|

Fieldbus Blocks

|

Resource, 3xTransducer, 6xAnalog Input (30 ms), PID (40 ms), Arithmetic, Input Selector, Output selector (65 ms) ,Signal Characterizer (75 ms)

|

|

Configuration Tools

|

Rosemount Radar Master, 375 Field Communicator, AMS Suite: Intelligent Device Manager, DeltaV or any other DD- or EDDL-compatible host-system.

|

Applications :

The Rosemount 5300 series is suitable for all types of processing industries including oil & gas production, refining, petrochemical, chemical, power, and water & waste treatment. The Rosemount 5300 offers radar level measurement benefits for a wide range of applications in these industries. Its probe guided radar signal combined with innovative engineering makes the 5300 virtually unaffected by process conditions and it has almost no installation restrictions. For more information about applications and how to select the correct GWR transmitter, click here

|

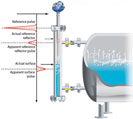

Combine Level And Interface Measurement

One 5300 transmitter will measure both the upper surface and the lower product interface in tanks with two products such as separators, settling tanks etc. This reduces the number of tank penetrations required. Use the 5300 with a single lead probe for reliable measurement of interface in crude oil and other liquids that create build-up.

|

|

|

Improved Performance in Liquified Gases

Being virtually maintenance-free and unaffected by turbulence and vapor, the Rosemount 5300 is perfect for liquid gas applications. The transmitter head can be serviced without breaching the tank atmosphere. Superior performance enables relible operation in LNG, NGL, LPG and anhydrous ammonia tanks.

|

|

|

Underground Benefits

Probes that are unaffected by high and narrow openings or nearby objects are available. This makes the 5300 the best choice for underground tanks, where the installation area is usually limited.

|

|

|

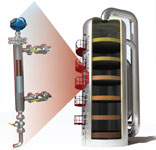

Minimize Risk In The Most Demanding Environments

The guided wave radar technology in the 5300 contains multiple layers of protection that enable reliable performance in high temperature and pressure tanks and bridles, on refinery distillation columns, and power feed-water tanks, etc. The measurement is not affected by density variations, low reflectivity media or the mechanical configuration of the bridle and the product inlet.

|

|

|

Solid Performance

Rosemount 5303 has a flexible single lead probe that measures solids with dielectric constants as low as 1.4. The measuring range is up to 160 ft (50 m), and the transmitter has robust EMI performance. Special probes for high physical weight loads are available. Solids applications with the 5300 include powders and granules, plastics such as PVC, cement, fly ash, corn etc.

|

|

|

Measure In Vessels With Turbulence, Vapor And Mechanical Structures

The Rosemount 5300 delivers uninterrupted level data where others fail. With Direct Switch Technology, the reflection back from the surface is two to five times stronger compared with other guided wave radars. The result is a superior ability to handle disturbing objects, probe coating, vapor and turbulence.

|

|

|

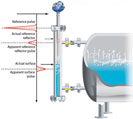

Accuracy in saturated steam applications

Saturated steam under high pressure slows down radar wave propagation giving an incorrect distance. This, together with varying pressure and/ or temperature is a challenge. The Rosemount 5300 with Dynamic Vapor Compensation (DVC) automatically compensates for this and maintains the level accuracy.

|

|

|

Level gauging in chambers

Guided Wave Radar is the ideal choice for measurements in chambers. It is unaffected by density changes, chamber configuration and has no moving parts which minimizes maintenance. This makes it an easy and reliable substitute for displacer technology.

|

|

|